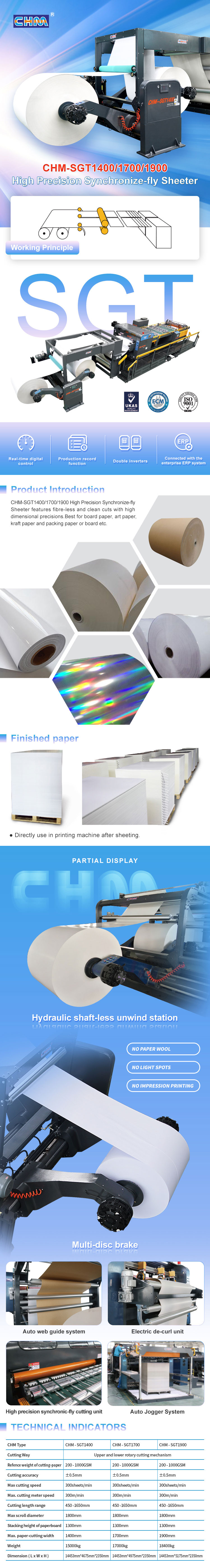

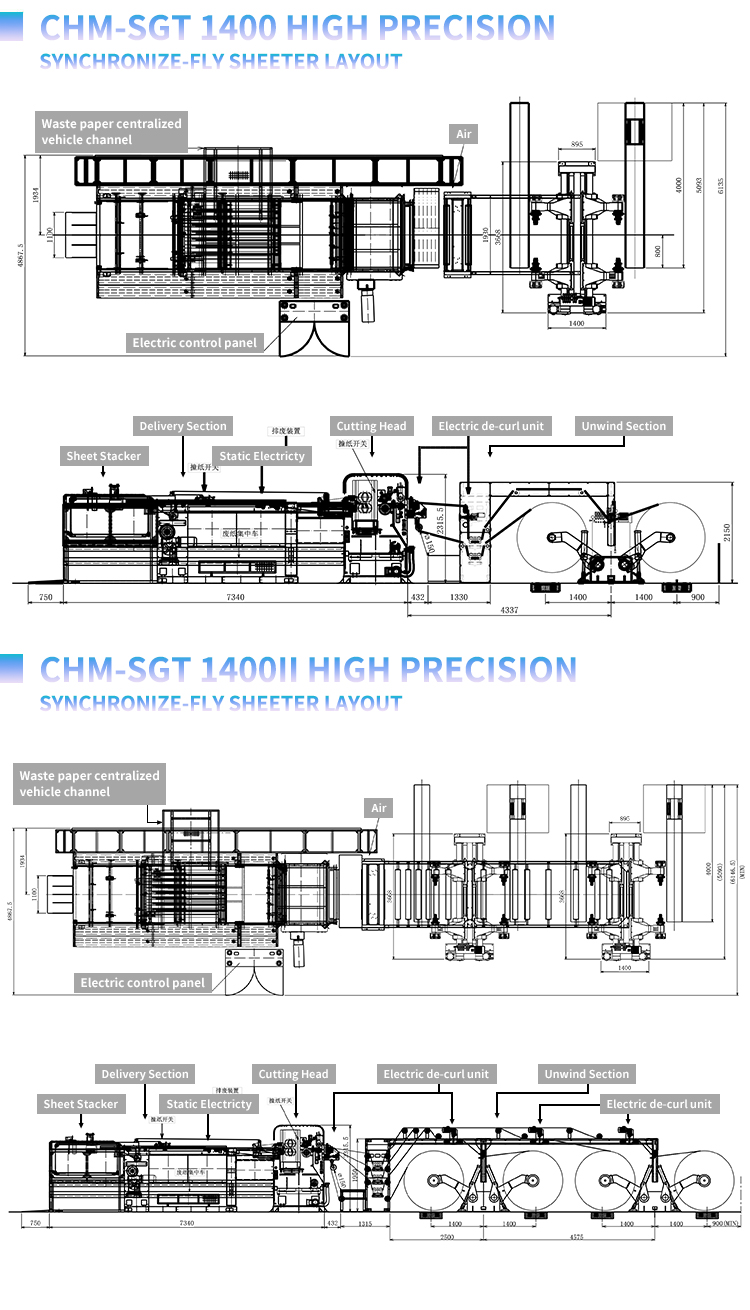

CHM-SGT1400/1700/1900 High Precision Synchronize-fly Sheeter

——

——

One good equipment for slitting coated paper - CHM SGT1700 High Precision synchronize-fly Sheeter Slitting

Hello Everyone! I am David from CHM, CHEUNG KONG MACHINERY(HK)LIMITED,

we are the professional sheeting machine manufacture and the leading paper sheeting solution provider in China.

Today, we share with you about the CHM SGT1700 High Precision synchronize-fly Sheeter,

the double rotary knife web paper slitting machine from CHM. This equipment integrates advanced technology.

In addition to stability, no paper wool, reducing loss and so on,

it performs very well in slitting coated paper!

It can also slitting 4 sheet at the same time production mode, high speed, high production capacity and high quality!

In the video, we customized maxcess slitting knife for customers.

Let's go into the production site together!

Hello Everyone! I am David from CHM, CHEUNG KONG MACHINERY(HK)LIMITED,

we are the professional sheeting machine manufacture and the leading paper sheeting solution provider in China.

Today, we share with you about the CHM SGT1700 High Precision synchronize-fly Sheeter,

the double rotary knife web paper slitting machine from CHM. This equipment integrates advanced technology.

In addition to stability, no paper wool, reducing loss and so on,

it performs very well in slitting coated paper!

It can also slitting 4 sheet at the same time production mode, high speed, high production capacity and high quality!

In the video, we customized maxcess slitting knife for customers.

Let's go into the production site together!

CHM Product Series

——

——

-

1400/1700/1900Precision High Speed Sheeter

-

SGT1400/1700/1900High Precision synchronize-fly Sheeter

-

A3/A4/A5 sizePaper sheeting and packaging production line

-

CHM-A4DBReam Paper Box Wrapping Machine

-

RMD120Stacking Machine

CHM-A4B A4 paper packaging production line equipment

This machine is a set of packaging production line equipment, which integrates electrical automation, PLC control system and mechanical automation. It is a complete set of packaging production line equipment for continuous production, which is composed of preparation, opening, memory transmission, packaging and discharging.